KCSL-200

AUTOMATIC PASTE(LIQUID)FILLING AND PACKAGING MACHINE

FEATURES:

1.Two lane design, saving personnel and space, more cost-effective. How many lanes of the machine can be customized according to customer requirements.

2.The horizontal seal and roller are driven by servo motor, touch and adjust by human-machine interface, and controlled by PLC, so that the actuators can accurately and automatically locate, adjust quickly and conveniently.

3.Through the roller extrusion type seal, even with the material in the seal, can also be sealed.Continuous filling and intermittent filling correspond flexibly.

4. The cutting position adjustment is driven by the motor independently and adjusted up and down on the touch screen, making it more convenient to adjust the cutting position of the bag length.

5. Precise temperature control, strong adaptability of packaging materials and high sealing strength.

6. Adopt integral collar molding machine, which is easy to shape and precise in bag making.

7. The frame of the whole machine is made of SUS304 stainless steel, and the part in contact with the raw materials is made of SUS316L stainless steel, which is safe, hygienic and easy to clean.

APPLICATION:

This machine is broadly used in packaging liquid soup,cosmetics,cleansing liquid and mayonnaie,which require high filling precision.

SPECIFICATIONS:

|

Filling

Product

|

Liquid &

Paste

|

|

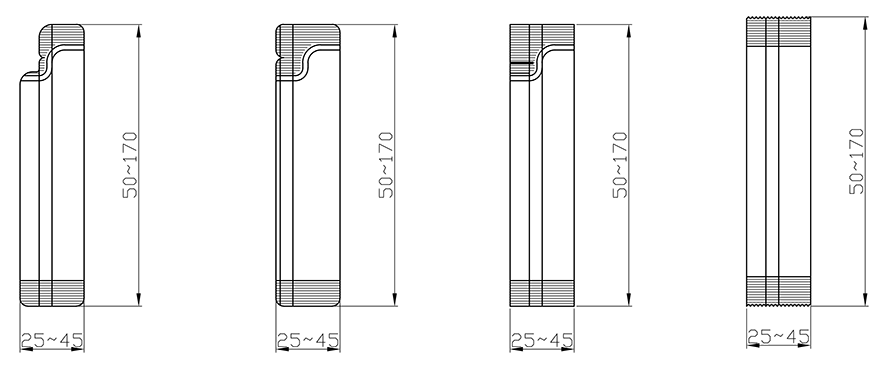

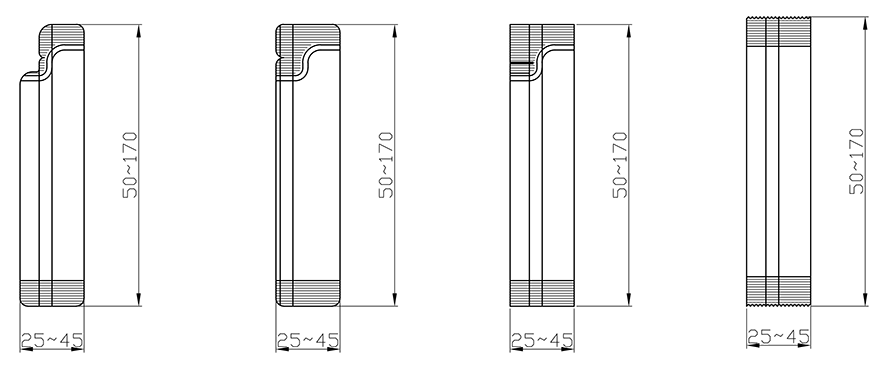

Pouch Pattern

|

Special

bottle neck design

|

|

Pouch Height Range

|

50-170mm

|

|

Pouch Width

|

25-45mm

|

|

Packaging Capacity

|

10-60

pouches per minute(1-lane)×lane amount

(depending on pouch height,film composition,product property,etc)

|

|

Filling Capacity

|

1-40ml

(depending on product property and filling device to be used)

|

|

Applicable

Film Width

|

120-200mm

|

|

Maximum Film

Roll Dia

|

¢

400mm

|

|

Power

Consumption

|

3-phase 380V 3.5kw

|

|

Air

Consumption

|

400L/min

(

0.4-0.5Mpa

)

|

|

Machine

Dimensions

|

1333mm(L)×1474mm(W)×2450mm(H)

|

|

Machine

Weight

|

Approx.400kg

|

PACKAGING STYLE: